Mochini o Thellang oa Tin Wire Laser Soldering

Sesebelisoa sa parameter

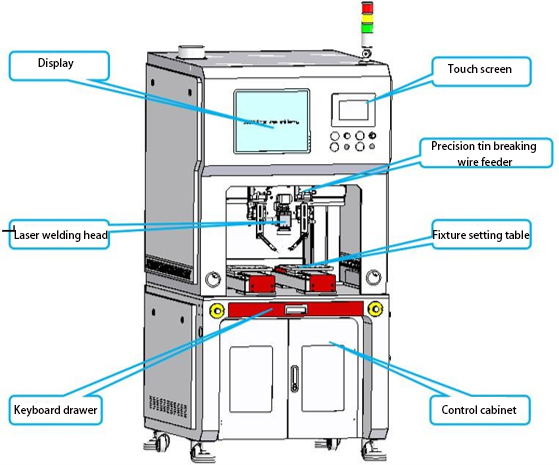

| Mohlala | GR-F-LS5442C1 |

| Likaroloana tsa mantlha | PLC, Enjine, Enjene |

| Palo ea li-volts | 220V |

| Hona joale | 10A |

| Boima ba 'mele | 400KG |

| Litekanyo | 920mm×1020mm×1800mm |

| Tšebeliso | terata soldering |

| Palo ea li-spindle | X, Y1, Y2, Z |

| Lintlha tsa bohlokoa tsa ho rekisa | Bophelo bo Bolelele ba Tšebeletso |

| Phepelo ea motlakase | AC220V 10A 50-60HZ |

| Leeto la sethala | X=500, Y=400, Z=200mm |

| Sebaka sa tšebetso | 350 * 350mm |

| Mofuta oa weld | Khoele ea lesela la laser |

| Mofuta oa laser | Laser ea semiconductor e khanyang e putsoa |

| Laser wavelength | 445nm |

| Matla a phahameng a tlhahiso ea laser | 40W |

| Fiber core bophara | 400um |

| Matla a mochine kaofela | 2.0KW |

| mokhoa oa ho phalla | Pholiso ea moea |

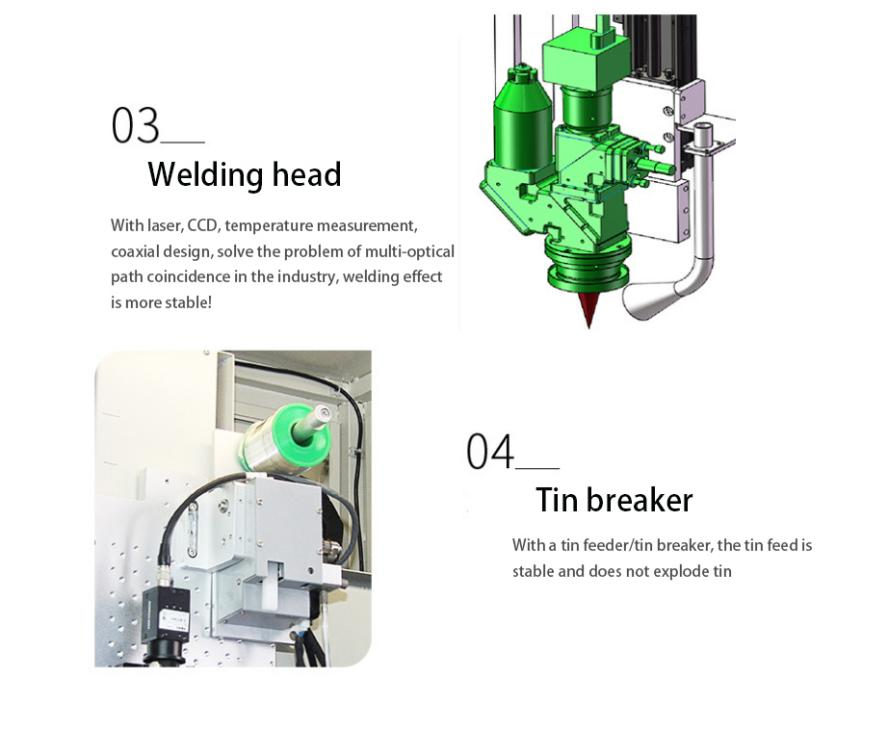

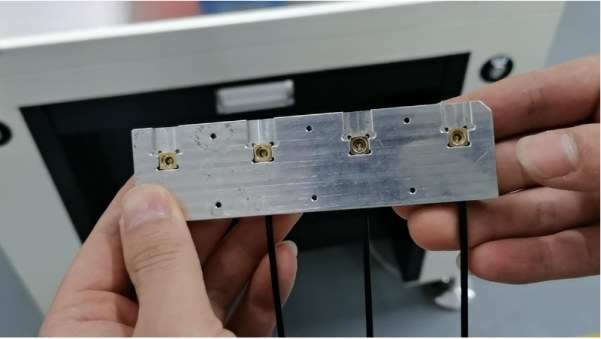

Likarolo tsa sesebelisoa

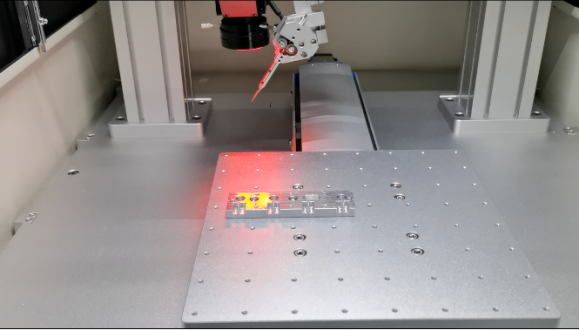

1. Ho nepahala ho phahameng: sebaka se khanyang se ka fihla boemong ba micron, 'me nako ea ho sebetsa e ka laoloa ke lenaneo, ho etsa

ho nepahala ho phahameng haholo ho feta mokhoa o tloaelehileng oa soldering.

2. Ts'ebetso e se nang puisano: mokhoa oa ho kopanya o ka phethoa ntle le ho kopana ka ho toba holim'a metsi, kahoo ha ho na khatello ea kelello e bakoang ke ho kopana le welding.

3. Litlhoko tsa sebaka se senyane sa ho sebetsa: lebone le lenyane la laser le nka sebaka sa tšepe ea solder, mme ts'ebetso e nepahetseng e boetse e etsoa.

e etsoa ha ho na le litšitiso tse ling ka holim'a workpiece.

4. Sebaka se senyenyane sa ho sebetsa: ho futhumatsa sebakeng seo, sebaka se amehileng ke mocheso se senyenyane.

5. Ts'ebetso ea ho sebetsa e bolokehile: ha ho na tšoso ea motlakase nakong ea ts'ebetso.

6. Mokhoa oa ho sebetsa o hloekile ebile o na le moruo: lisebelisoa tsa laser processing, ha ho na litšila tse hlahisoang nakong ea ts'ebetso.

7. ts'ebetso e bonolo le tlhokomelo: ts'ebetso ea laser soldering e bonolo, tlhokomelo ea hlooho ea laser e bonolo.

8. Bophelo ba tšebeletso: Bophelo ba laser bo ka sebelisoa bonyane lihora tsa 10,000, ka bophelo bo bolelele le ts'ebetso e tsitsitseng.

Lethathamo la kopo

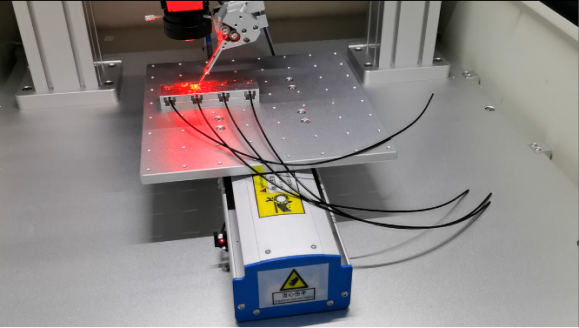

1. Mohala, sehokelo sa betri;

2. Boto e bonolo le e thata;

3. Mabone a koloi, mabone a LED;

4. Sehokelo sa USB, plug-in ea capacitor resistor;