In-line AI Version Top and Bottom Lighting AOI Machine Automated Optical Inspection System bakeng sa PCBA Wave Soldering

Lifofane, li-smartphone, tlhahiso ea likoloi, matlapa, FPCs, lisebelisoa tsa digital, lipontšo, mabone a ka morao, li-LED, lisebelisoa tsa bongaka, li-Mini LED, li-semiconductors, li-control tsa indasteri le likarolo tse ling tsa elektroniki.

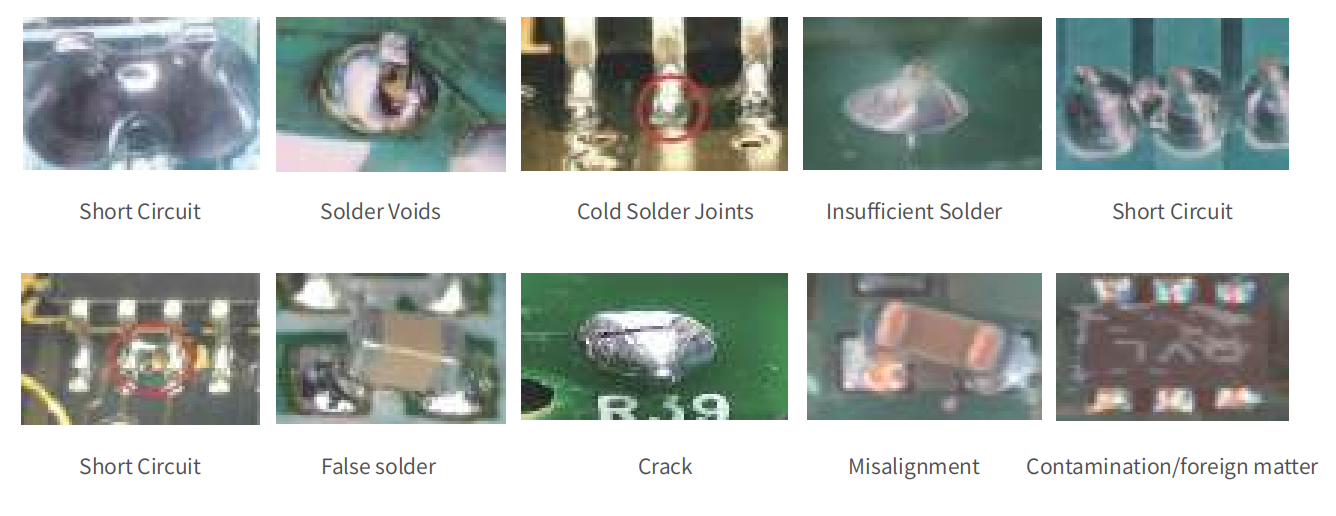

Mefokolo ea Tlhahlobo

Litšitiso, borokho ba solder, solder e sa lekaneng / e feteletseng, li-lead tse sieo, li-voids, libolo tsa solder, likarolo tse sieo tse fosahetseng, jj.

| AI Intelligent Assisted Modeling: Ho etsa mohlala ka potlako ntle le ho seta paramethara. | ||

| Likarolo tsa mantlha: Li-algorithms tsa ho ithuta ka botebo, mananeo a potlakileng, koetliso ea mohlala e nepahetseng haholo, taolo e hole. | ||

| One-Click Intelligent Search: E ts'ehetsa mefuta ea likarolo tse 80+, e tsamaellanang le liphapano tsa morphological. E khetholla likarolo ka bo eona le ho hlopha mefokolo. | ||

| Sistimi ea Snapshot ea Boto ea Pele ea Marang-rang bakeng sa Moloko oa Sets'oants'o sa Lenaneo le Ikemetseng. | ||

| Bokhoni bo Matla ba ho Ithuta: E ts'ehetsa thuto e tsoelang pele ea keketseho (e ntlafala ka koetliso e eketsehileng). | ||

| Ts'ebetso e tsoetseng pele ea Temoho ea Sebopeho: E hloaea litlhaku tse fapaneng ka bokhabane bo phahameng. | ||

| Litšoantšo tse ka holimo, litšoantšo tse ka tlaase, le litšoantšo tse peli (holimo + tlase) li ka lokisoa habonolo ho ikamahanya le maemo a mangata. | ||

| Moralo le liteko tsa meralo ea meralo ea mesebetsi e mengata, e ts'ehetsa khatiso ea inthaneteng ka nako ea nnete, ka khokahano ea othomathiki ha e bolokoa. | ||

| SPC | E fana ka lintlha tsa tlhahlobo ea lipalo-palo tsa nako ea nnete le lichate tse fapaneng tsa lipalo | |

| Phatlalatso ea Lentsoe | E tšehelitsoe | |

| Tlhahlobo ea Merero e Mengata | Tlhahiso ea li-co-line bakeng sa mefuta e mengata ea mechini (likhetho tse 6 li teng) | |

| Tataiso ea Tsamaiso ea Boto | Phallo ea mahlakore a mabeli | |

| Tlhahlobo ea Merero e Mengata | E tšehelitsoe | |

| Lintho tsa Tlhahlobo | Tlhahlobo e ka tlase ea ho nahana (Soldering Defects): Lipotoloho tse khutšoane, koporo e pepesitsoeng, ho ba sieo ha likarolo tsa lead, li-pinholes, solder e sa lekaneng, 'mele oa likarolo tsa SMT, le litaba tsa soldering. | |

| Litlhokomeliso tsa Mantsoe a Tloaelehileng | E tšehelitsoe | |

| Remote Control & Debugging | E tšehelitsoe | |

| Sehokelo sa Puisano | Sehokelo sa SMEM4 | |

|

Sebopeho sa Hardware | Mohloli oa Leseli | RGB kapa RGBW Integrated Ring Light |

| Lense | Lense ea 15/20μm e Phahameng ka ho Fetisisa | |

| Khamera | 12-Megapixel High-Speed Industrial Khamera | |

| Khomphuta | Intel i7 CPU / NVIDIA RTX 3060 GPU / 64GB RAM / 1TB SSD / Windows10 | |

| Hlokomela | 22" FHD Display | |

| Boemo | L1100× D1450× H1500 limilimithara | |

| Tšebeliso ea Matla | AC 220V±10%, 50Hz | |

| Boima ba mochini | 850KG | |

Ngola molaetsa wa hao mona mme o re romele wona