High Precision Duplex Laser Solder Ball Welding Machine

Sesebelisoa sa parameter

| tem | boleng |

| Mofuta | Mochini oa Soldering |

| Boemo | E ncha |

| Liindasteri tse sebetsang | indasteri ea fuse, indasteri ea semiconductor, indasteri ea puisano |

| Tlaleho ea Teko ea Mechini | Fanetsoe |

| Mofuta oa Papatso | Sehlahisoa se Tloaelehileng |

| Warranty ea likarolo tsa mantlha | Lilemo tse 1.5 |

| Likaroloana tsa mantlha | PLC, Motor, Sekepe sa khatello |

| Sebaka sa Showroom | Ha ho letho |

| Sebaka sa Tšimoloho | China |

| Guangdong | |

| Lebitso la Brand | MONAHANA |

| Palo ea li-volts | 220V |

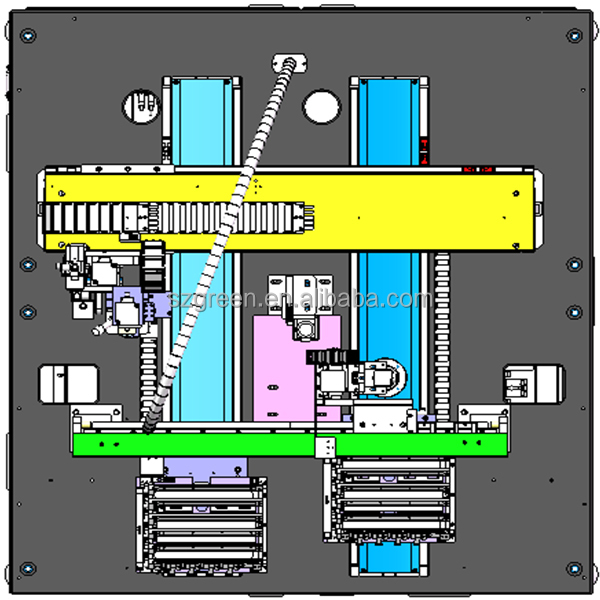

| Litekanyo | 100*110*165(cm) |

| Tšebeliso | terata ya solder |

| Tiisetso | 3Lilemo |

| Lintlha tsa bohlokoa tsa ho rekisa | Ho nepahala ho phahameng |

| Boima (KG) | 500KG |

| Mohlala | LAB201 |

| Litlhaloso tsa bolo ea solder | 0.15-0.25mm/0.3-0.76mm/0.9-2.0mm(Ha u rata) |

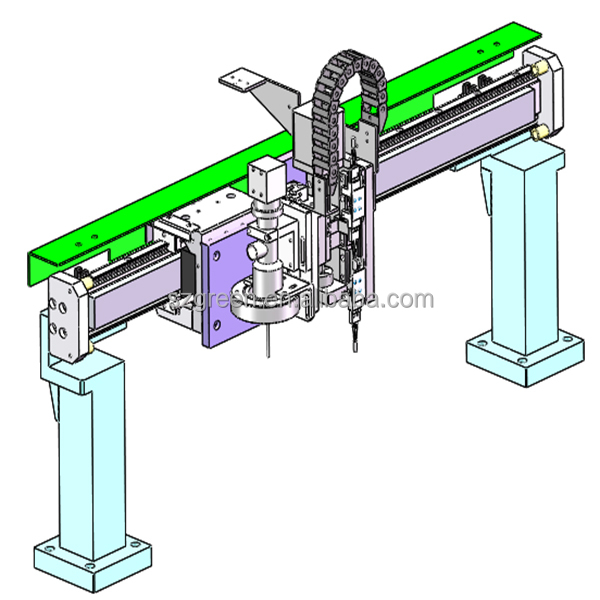

| Sistimi ea boemo ba pono | CCD, Qeto e ± 5um |

| Lipikselse tsa khamera | Lipikselse tse limilione tse 5 |

| Mokhoa oa ho laola | PLC+PC Taolo |

| Ho nepahala ho pheta-pheta ka mechine | ± 0.02 limilimithara |

| Sebaka sa tšebetso | 200mm * 150mm (Ho ka khoneha) |

| Sebelisa matla | <2KW/H |

| Mohloli oa moea | Moea o hatelitsoeng>0.5 MPa nitrogen>0.5MPa |

| Demension ea ka ntle(LW*H) | 1000*1100*1650(mm) |

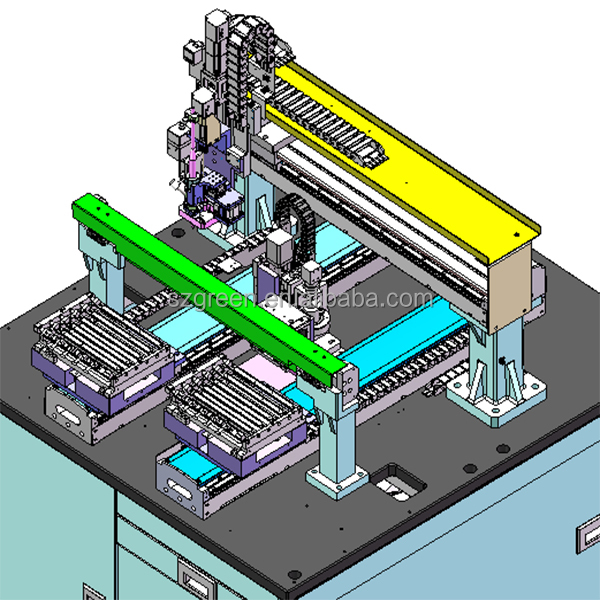

Likarolo tsa sesebelisoa

1. Ts'ebetso ea ho futhumatsa le marotholi e potlakile 'me e ka phethoa ka hare ho 0.2s;

2. Qetella ho qhibiliha ha bolo ea solder ka nozzle ea solder ntle le ho fafatsa;

3. ha ho phallo, ha ho na tšilafalo, ho eketsa bophelo ba lisebelisoa tsa elektroniki;

4. Bophahamo bo fokolang ba bolo ea solder ke 0.15mm, e lumellanang le mokhoa oa tsoelo-pele oa ho kopanya le ho nepahala;

5. Welding ea manonyeletso a fapaneng a solder e ka phethoa ka khetho ea boholo ba bolo ea solder;

6. E tsitsitseng boleng ba tjheseletsa le sekhahla se phahameng sa chai;

7. Sebelisana le tsamaiso ea boemo ba CCD ho finyella litlhoko tsa tlhahiso ea boima ba kopano;

8. UPH > lintlha tse 8000, lihlahisoa > 99% (ho fapana ho ea ka sehlahisoa se fapaneng)

Sebaka sa kopo

kh'amera/mojule ea CCM, monoana oa khauta/FPC, terata, sesebelisoa sa puisano, sesebelisoa sa optical, indasteri ea fuse, solder ea indasteri ea semiconductor.

Sebaka sa Kopo

Laser solder ball welding e hlokomela sehlopha se nepahetseng: PCB pad le khokahano ea solder ea menoana ea khauta, FPC le PCB welding, rod ea terata le

PCB tjheseletsa, karolo ea THT plug-in sesebelisoa soldering. Lihlahisoa tse nang le li-PIN ka lehlakoreng le le leng 'me li kopanya lihlahisoa tse nang le li-PIN ka bobeli

mahlakoreng, le lihlahisoa tse ling tse ngata tse nepahetseng.

Ho paka & Delivery