Tšebeliso ea mohala oa morao-rao oa SMT indastering ea elektroniki ea 3C

GREEN ke Kgwebo ya Naha ya High-Tech e inehetseng ho R&D le ho etsa dikopano tsa elektronike tse itirisang le thepa ya ho paka le ho etsa diteko tsa semiconductor.

Ho sebeletsa baetapele ba indasteri joalo ka BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, le likhoebo tse ling tse 20+ tsa Fortune Global 500. Molekane oa hau eo u mo tšepang bakeng sa litharollo tse tsoetseng pele tsa tlhahiso.

Surface Mount Technology (SMT) ke ts'ebetso ea mantlha tlhahisong ea sejoale-joale ea elektroniki, haholo indastering ea 3C (khomphutha, puisano, lisebelisoa tsa elektroniki tsa bareki). E kenya lisebelisoa tse se nang lead / short-lead (SMDs) ka ho toba holim'a marang-rang a PCB, e leng ho nolofalletsang lihlahisoa tse phahameng, tse nyenyane, tse bobebe, tse ka tšeptjoang, le tse phahameng.

□ Lihlahisoa tsa elektroniki tsa 3C (tse kang li-smartphones, matlapa, lilaptop, li-smartwatches, li-headphones, li-routers, joalo-joalo) li hloka miniaturization e feteletseng, li-profiles tse nyane, ts'ebetso e phahameng,le ka potlako

iteration.SMT mela e sebetsa e le sethala sa mantlha sa tlhahiso se sebetsanang le litlhoko tsena ka nepo.

□ Ho Finyella Miniaturization e Feteletseng le Boima bo bobebe:

SMT e thusa tlhophiso e teteaneng ea likaroloana tse nyane (mohlala, 0201, 01005, kapa li-resistors/capacitor tse nyane; li-chips tsa BGA/CSP tse hlakileng) ho li-PCB, tse fokotsang boto ea potoloho haholo.

footprint, bophahamo ba sesebelisoa ka kakaretso, le boima ba 'mele - sesebelisoa sa bohlokoa bakeng sa lisebelisoa tse nkehang joaloka li-smartphone.

□ Ho nolofaletsa Khokahano ea Boima bo Phahameng le Ts'ebetso e Phahameng:

Lihlahisoa tsa sejoale-joale tsa 3C li hloka ts'ebetso e rarahaneng, e hlokang li-PCB tsa "high-density interconnect" (HDI) le litsela tse rarahaneng tsa multilayer. Bokhoni ba ho beha ka nepo ba SMT bo theha

motheo oa likhokahano tse tšepahalang tsa lithapo tse phahameng haholo le li-chips tse tsoetseng pele (mohlala, li-processor, li-module tsa memori, li-unit tsa RF), ho netefatsa ts'ebetso e nepahetseng ea sehlahisoa.

□ Ho Matlafatsa Matla a Tlhahiso le ho Fokotsa Litšenyehelo:

Mehala ea SMT e fana ka li-automation tse phahameng (ho hatisa, ho beoa, ho phalla hape, tlhahlobo), lisebelisoa tse potlakileng haholo (mohlala, litefiso tsa ho beoa tse fetang 100,000 CPH), le ho kenella ka letsoho ho fokolang. Sena

e netefatsa botsitso bo ikhethang, litefiso tse phahameng tsa chai, 'me e theola haholo litšenyehelo tsa yuniti ka tlhahiso ea bongata-ho lumellana ka ho phethahetseng le litlhoko tsa lihlahisoa tsa 3C bakeng sa nako e potlakileng ea ho ea mmarakeng le

theko ea tlholisano.

□ Ho netefatsa ho Tšepahala le Boleng ba Sehlahisoa:

Mekhoa e tsoetseng pele ea SMT-ho kenyeletsoa khatiso e nepahetseng, ho behoa ka mokhoa o nepahetseng haholo, profiling e laoloang, le tlhahlobo e matla ea inline-tiisetso ea ho lumellana ha solder le

tsepahala. Sena se fokotsa haholo mefokolo e joalo ka manonyeletso a batang, borokho le ho se tsamaisane hantle, ho fihlela litlhoko tse thata tsa ts'ebetso ea lihlahisoa tsa 3C ka thata.

tikoloho (mohlala, ho thothomela, ho palama baesekele e futhumetseng).

□ Ho Ikamahanya le Phetoho e Potlakileng ea Sehlahisoa:

Ho kopanngoa ha melao-motheo ea Flexible Manufacturing System (FMS) ho nolofalletsa mela ea SMT hore e fetohe ka potlako pakeng tsa mefuta ea lihlahisoa, e arabela ka matla ho fetoha ka potlako.

litlhoko tsa 'maraka oa 3C.

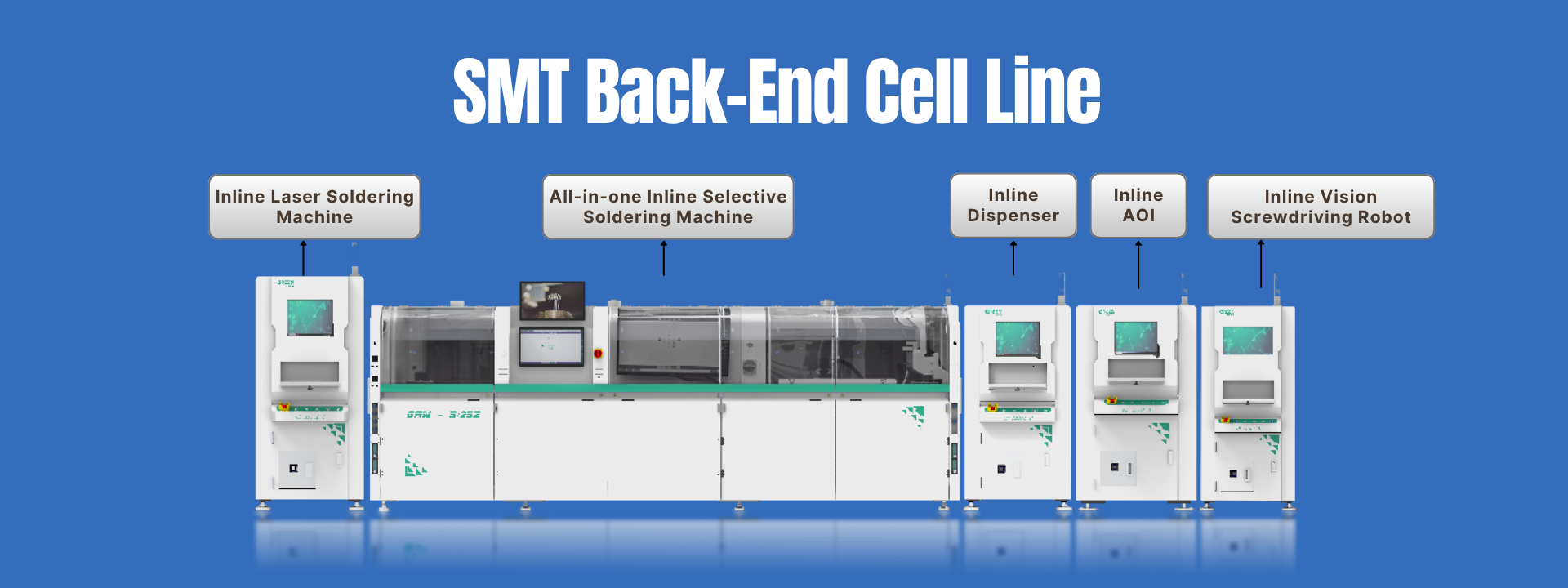

Laser Soldering

E nolofalletsa solder e laoloang ke mocheso ka nepo ho thibela tšenyo ea likarolo tsa thermosensitive. E sebelisa ts'ebetso e seng ea puisano e felisang khatello ea maikutlo, ho qoba ho falla ha likarolo kapa PCB deformation - e ntlafalitsoeng bakeng sa libaka tse kobehileng / tse sa tloaelehang.

Khetho ea Wave Soldering

Li-PCB tse nang le baahi ba bangata li kena ka ontong ea reflow, moo boemo ba mocheso bo laoloang hantle (ho futhumatsa, ho kolobisa, ho phalla, ho pholisa) ho qhibilihisa peista ea solder. Sena se nolofalletsa ho kolobisa liphahlo le likarolo tsa likarolo, ho etsa li-bond tse ka tšeptjoang tsa metallurgic (linonyello tsa solder), tse lateloang ke ho tiisa holim'a pholileng. Taolo ea curve ea mocheso ke ea bohlokoa bakeng sa boleng ba weld le ts'epahalo ea nako e telele.

Phatlalatso e Felletseng e Phahameng ka ho Fetisisa e Phahameng ka ho Fetisisa

Li-PCB tse nang le baahi ba bangata li kena ka ontong ea reflow, moo boemo ba mocheso bo laoloang hantle (ho futhumatsa, ho kolobisa, ho phalla, ho pholisa) ho qhibilihisa peista ea solder. Sena se nolofalletsa ho kolobisa liphahlo le likarolo tsa likarolo, ho etsa li-bond tse ka tšeptjoang tsa metallurgic (linonyello tsa solder), tse lateloang ke ho tiisa holim'a pholileng. Taolo ea curve ea mocheso ke ea bohlokoa bakeng sa boleng ba weld le ts'epahalo ea nako e telele.

Mochini oa AOI

Tlhahlobo ea AOI ka mor'a Phallo:

Ka mor'a hore reflow soldering, litsamaiso tsa AOI (Automated Optical Inspection) li sebelisa lik'hamera tse nang le qeto e phahameng le software ea ho sebetsana le litšoantšo ho itlhahloba ka bo eona boleng ba motsoako oa solder ho PCBs.

Sena se kenyelletsa ho lemoha mefokolo joalo ka:Mefokolo ea Solder: Solder e sa lekaneng / e feteletseng, manonyeletso a batang, borokho.Mefokolo ea Likarolo: Ho se lumellane, likarolo tse sieo, likarolo tse fosahetseng, polarity e khutlisitsoeng, lejoe la mabitla.

Joalo ka sebaka sa bohlokoa sa taolo ea boleng meleng ea SMT, AOI e netefatsa bots'epehi ba tlhahiso.

Pono-Guided Inline Screwing Machine

Ka har'a mela ea SMT (Surface Mount Technology), tsamaiso ena e sebetsa e le thepa ea morao-rao, e bolokang likarolo tse kholo kapa likarolo tsa moralo ho li-PCB-tse kang licheso tsa mocheso, li-connectors, li-brackets tsa matlo, joalo-joalo E na le ho fepa ka mokhoa o itekanetseng le ho laola torque e nepahetseng, ha e ntse e lemoha mefokolo e kenyelletsang li-screws tse hlolohetsoeng, li-thread-threaded fasten, li-threaded striped fasten.